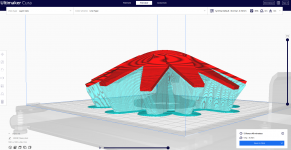

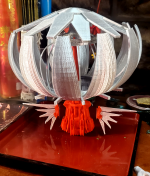

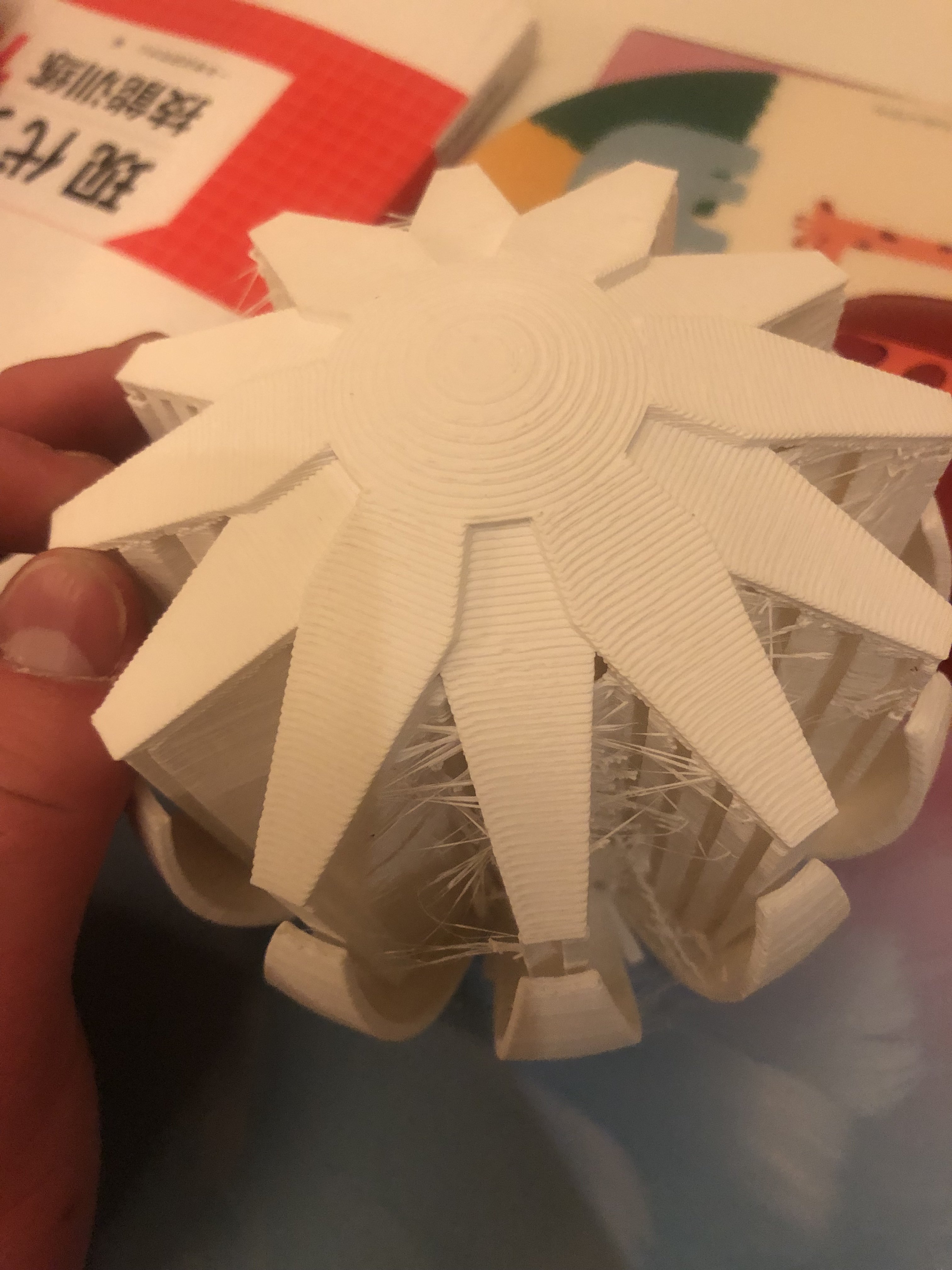

This looks great! I've also tried printing, but it sucks...

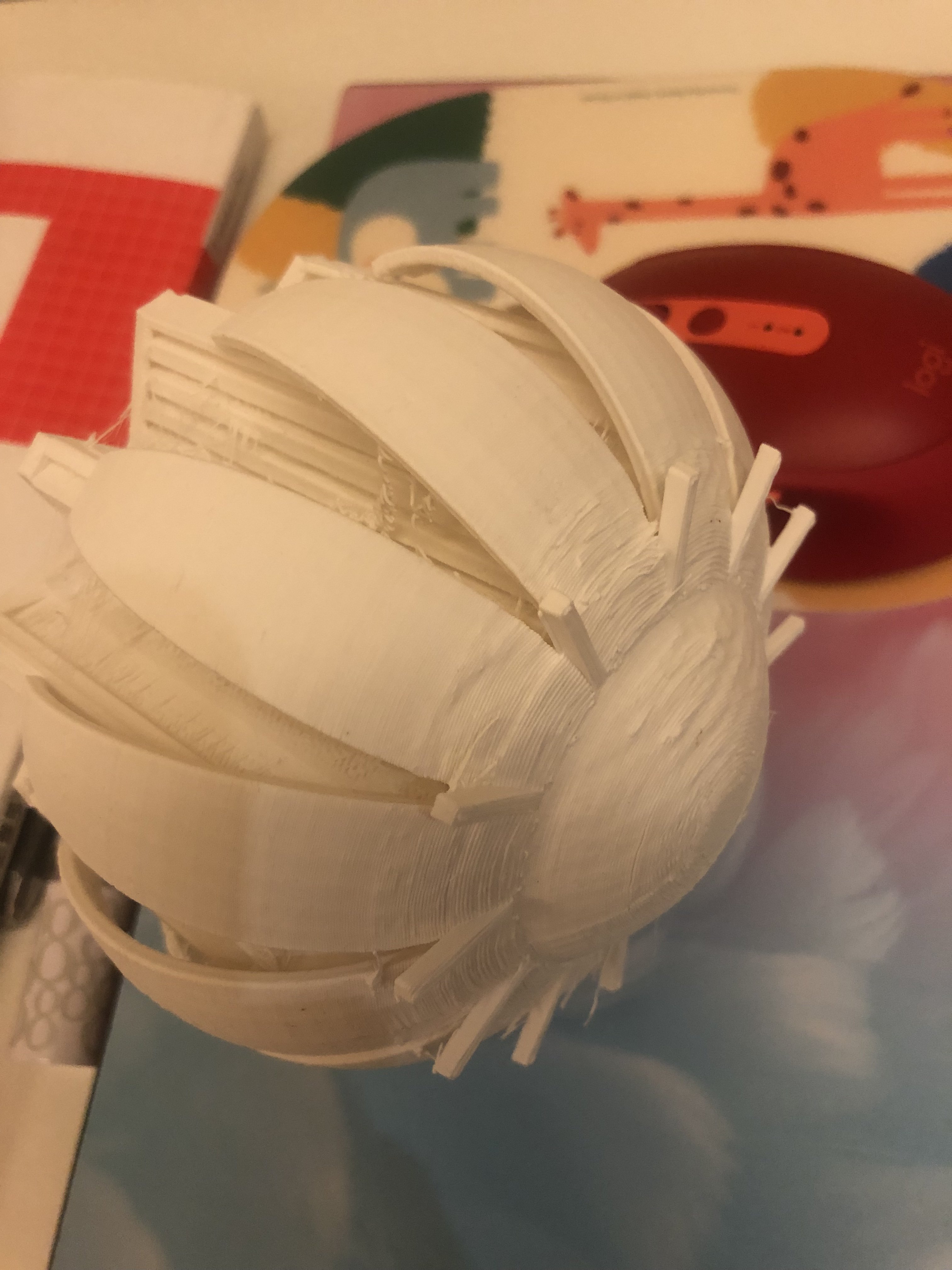

I'm now trying to figure out how to do simple sculpting with aluminum or other materials. My idea is to split it into upper and lower parts and then weld the middle part using wire/thin carving

I'm now trying to figure out how to do simple sculpting with aluminum or other materials. My idea is to split it into upper and lower parts and then weld the middle part using wire/thin carving